In the fast lane:

Our research projects

Shortening personnel training periods with AI assistance systems. Autonomous driving made safe, even in complex situations. We conduct research on projects for the future, utilizing both the knowledge of our XITASOnians and that of our large network.

Highlights from our research projects:

VALISENS: sensor technology for autonomous driving.

Computer Vision – Sensor Fusion – Deep Learning – V2X – GAIA-X

Self-driving cars are a real challenge. Dealing with complex traffic situations is still highly error prone. What if a child spontaneously runs a red light? Or if one car takes another car's right of way at a crossing? Just the right project for XITASO. Together with our project partners, we have one common goal: to create a robust sensor system that effectively takes external influences into account and thereby increases the safety of autonomous vehicles in challenging traffic situations.

The VALISENS project (German acronym for Valid Innovative Overall Sensor System for Cooperative Automated Driving), funded by the Federal Ministry for Economic Affairs and Climate Protection, has been ongoing since January 1st, 2023.

It targets the reliable and trustworthy sensorial perception for autonomous driving in intersection traffic. For this purpose, data from infrared cameras are merged with data from other sensors like classic RGB cameras, LiDARs and radars through V2X communication (vehicle-to-everything). The focus is on the development of AI-based multi-perspective and multi-modal sensor fusion as well as object recognition and their transfer to driving scenarios. Particular attention is paid to the robustness under various external conditions when fusing infrared images with classic camera images.

ADELeS : knowledge based machine learning for removal of anomalies.

Machine Learning – Neuro-Symbolic AI

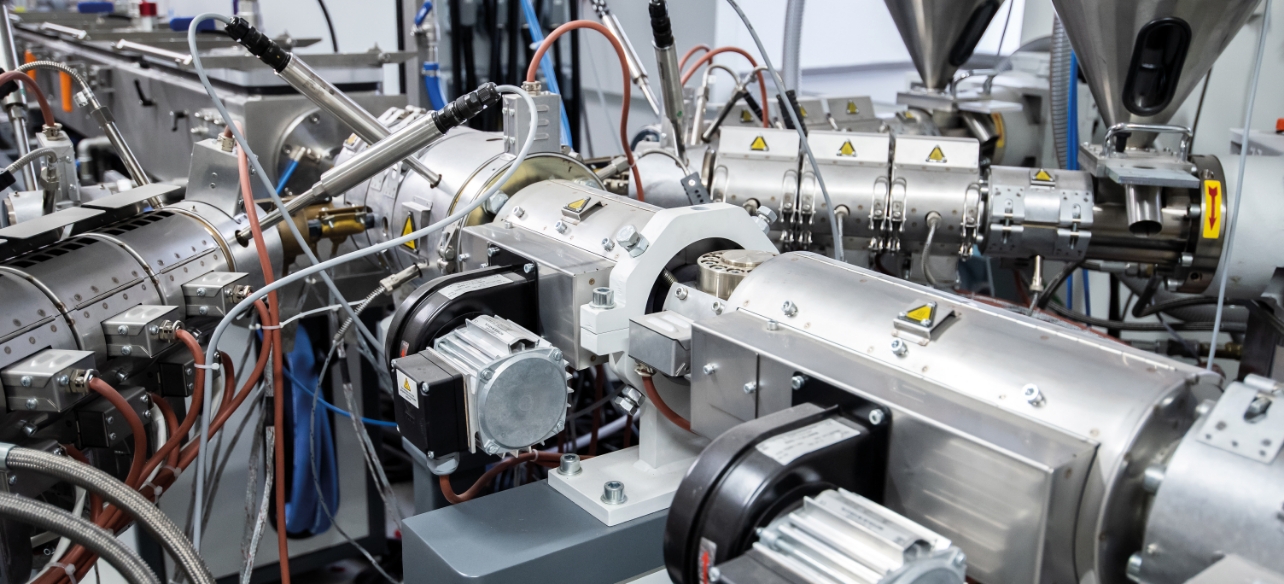

In our applied research project, ADELeS (German acronym for anomaly mitigation through extracted expert knowledge and learning systems), we are developing an AI based assistance system to recognize and correct quality deviations during production.

Why is this so important? To operate complex production systems, experienced specialized personnel are needed. But they are hard to find. Especially when employees change jobs or retire, their knowledge is lost. For this reason, production systems must also be able to be operated by less experienced personnel. One key to this can be to enhance production machines and systems with intelligent assistance systems to reduce training times and thereby increase overall productivity.

To achieve this, we work with data-based knowledge extraction. After all, a major hurdle is often that pure machine learning is not directly applicable. This results, on one hand, from the inherent data scarcity, and on the other hand, from the problem of generalizing the learned models, for example to different product variations. Consequently, we use a newly developed method for extracting knowledge from experienced machine operators. We merge this knowledge with machine learning using hybrid, neuro-symbolic AI methods. The resulting innovative assistance system thus leads to better quality of the manufactured products and lowers the entry barriers for machine operators.

Want more innovative impulses?

You can find many more research projects on our website:

This might also interest you:

Driving technology

From groundbreaking technologies to revolutionary applications. We create sustainable growth by working in long-term partnerships to shape the technology …

Fully geared towards AI

As experts for high-end software engineering, we always have to be up to date, to drive digital transformation. Topics like data science …

Authentic. Transparent.

100% XITASO.

We invited our management, Uli, Martin and Michi to an interview. The result is an exciting look back on 2023 with a lot of valuable insights, as well as a look forward to 2024. And naturally our new claim …